Equipment management is no longer just about “what’s available in the yard.” It’s about strategy. Data. Control. And ultimately, profitability.

Unfortunately, many companies still rely on outdated spreadsheets, siloed systems, or manual processes to track thousands of tools and assets across multiple jobsites. What’s missing isn’t just better technology, it’s a better framework for thinking about inventory and equipment as operational enablers, not just physical assets.

Let’s explore what that level of management actually looks like.

Categorizing Assets with Purpose

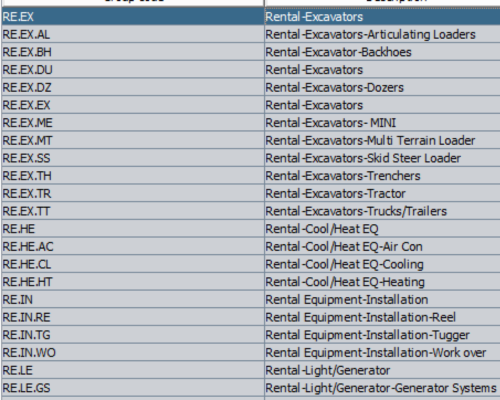

At the core of smarter equipment operations is structure. Being able to group and classify tools and machinery, from power drills to 40-ton cranes, allows you to think beyond serial numbers and start managing by operational value.

With the right system, each asset can be:

- Assigned to a specific equipment type (e.g., heating units, cooling systems, generators)

- Grouped into custom categories for easier search, filter, and reporting

- Rolled up into dashboards that show fleet utilization at a strategic level

This means you can zoom in on a single heater that’s past due, or zoom out to see how all climate control units across job sites are performing.

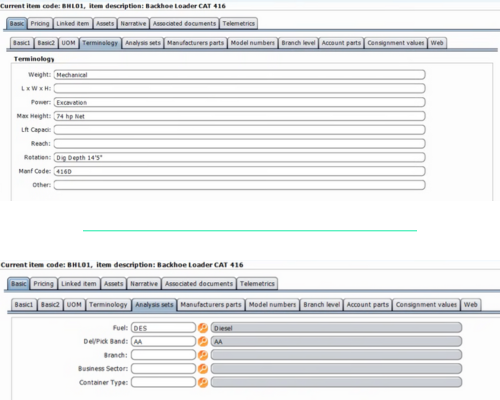

Custom Fields That Reflect Your Business

Every company’s fleet is different. Whether you’re tracking OSHA-required inspection dates, fuel types, certifications, or cost codes, a one-size-fits-all approach doesn’t cut it.

That’s why custom fields by equipment type are so important.

You can:

- Add dropdown menus or free-text fields for specific asset classes

- Track information at both the type and individual asset level

- Create fields that match your internal processes, not force your team to adapt to the software

This flexibility allows your field teams, warehouse managers, and compliance staff to all access the data that matters most to them, without clogging the system with irrelevant fields.

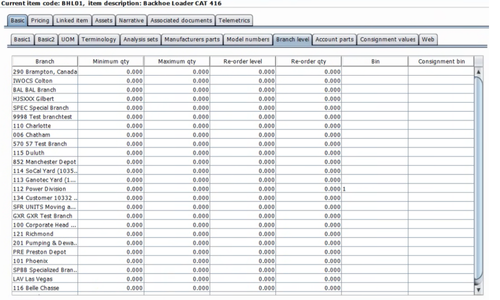

Proactive Alerts That Keep You Ahead

It’s not enough to know what you have. You also need to know what’s missing, what’s low, and what’s overdue.

With automated low stock and overdue return alerts, equipment managers can:

- Set thresholds by location and equipment type

- Get notified before materials run out or when tools are missing past return dates

- Trigger automatic replenishment requests or stock transfers

Instead of scrambling when inventory runs low, teams can stay ahead of the curve and reduce downtime, keeping jobs moving and projects on schedule.

The ability to categorize, customize, and proactively manage equipment may sound like a small detail, but it’s the foundation for a more strategic, data-driven equipment operation. When your system reflects the way you work, every team benefits, from procurement to project management to compliance.

Want to see what this looks like in action?

Explore how RentalResult helps enterprise construction companies move from reactive equipment tracking to fully optimized fleet management. Schedule a call today.